Industrial power engineering

We participate in the welding works during the construction and repairs of the power units, pipes, and steel structures as a part of our business operations.

The high quality of implemented services makes that the group of our satisfied customers is still growing.

Industrial systems

We perform the erection of the tanks, with the supporting structures and pipelines made of stainless and carbon steel, and conveyors or feeders.

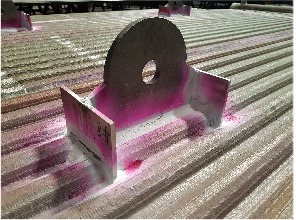

INCONEL® Cladding

We provide the INCONEL® 625/628 overlay welding services using the MIG and TIG methods in the location designated by the customer. The works are carried out during the service periods when it is required to re-apply the protective layers on the worn surfaces of the pipes as well as during the construction of new power units in the locations of boiler’s connections that require refilling with the INCONEL® layer.

Heat treatment

We provide the local preheating services for welding and heat processing after welding the metal components with the resistance devices (power from 65 to 130 kW) using from 6 to 24 independent heating ducts. The temperature charts can be recorded in digital and paper versions.

We provide our services in power plants, refineries, paper factories, and production plants.

Production

We deal with the production of pipelines, supports, steel structures, and platforms as a part of our business activities. We offer also CNC plasma and oxy-fuel cutting services for the metal sheets.

We are the holder of the certificates

- TUV PN-EN 1090-2

- PN-EN 3834-2

- AD 2000-Merkblatt

- UDT certification

We are responsible for

- procurement of material

- high standard prefabrication and welding according to client documentation

- sandblasting and painting/galvanizing

- NDT testing

- as-build documentation

- transport to indicated location

Employees outsourcing

An advantage of our company is customer support at every stage of the construction ensured by the carefully chosen erection and welding crews send to the location designated by the customer within 24 hours from sending of the request. Thanks to us the customer can be sure that the working personnel is properly trained, and has the required skills and the certificates required to execute the given task. Our team consists of charge-hands, independent fitters able to read the isometric/technical drawing, erectors, TIG, MIG, and E welders, quality inspectors, and welding engineers.

We are very flexible and accept short-term orders. We immediately respond to the customer’s needs. We are looking forward to cooperating with companies from all around the world!